Object Detection and Avoidance- Distance sensors are widely used to detect the presence of objects along the production line.

- In automated manufacturing processes, these sensors can identify the position and movement of objects, ensuring that machinery operates smoothly and without collisions.

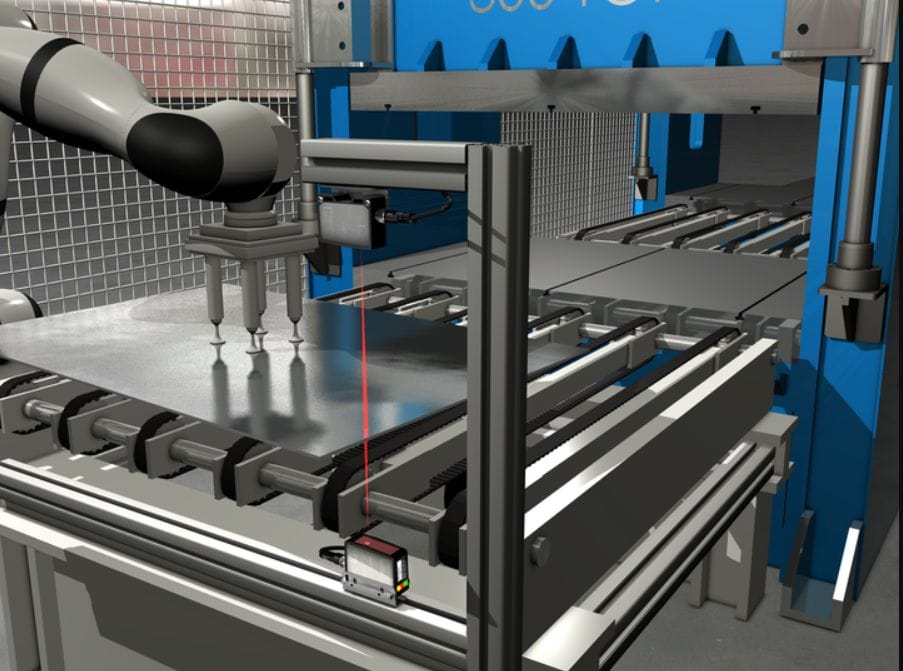

| Conveyor Belt Systems- Distance sensors are integrated into conveyor belt systems to monitor the position of products.

- They help regulate the flow of items, ensuring proper spacing and preventing jams or overlapping on the conveyor.

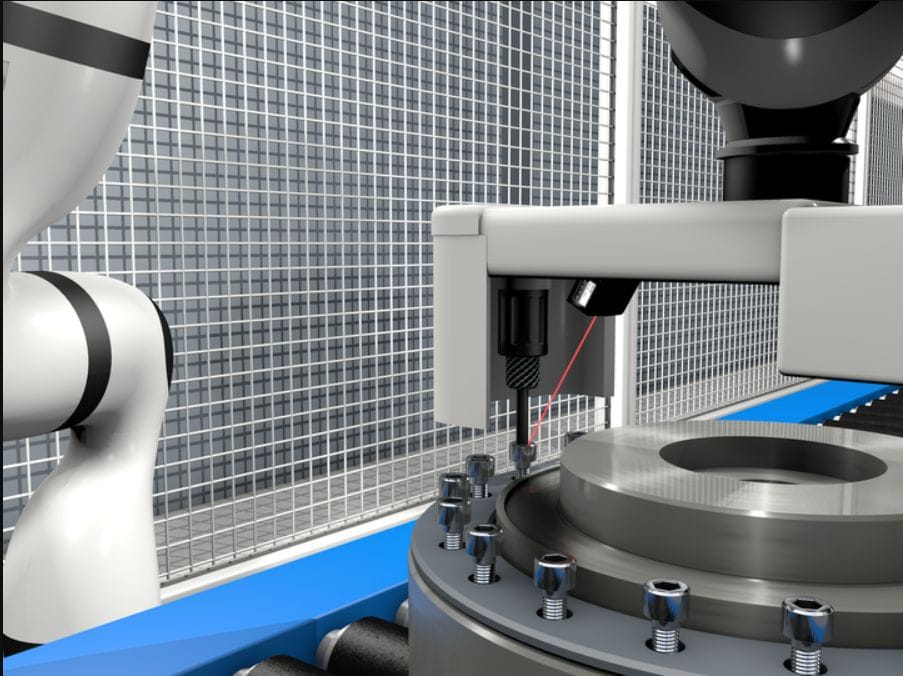

| Robotic Guidance- In robotic applications, distance sensors provide crucial input for navigation and guidance.

- Robots equipped with these sensors can accurately determine the distance to objects, allowing for precise movements and manipulation of items in their environment.

|

Palletizing and Depalletizing- Distance sensors assist in automating the palletizing and depalletizing of goods in warehouses and manufacturing facilities.

- They enable robotic arms to identify the position and height of items on pallets, facilitating efficient stacking and destacking processes.

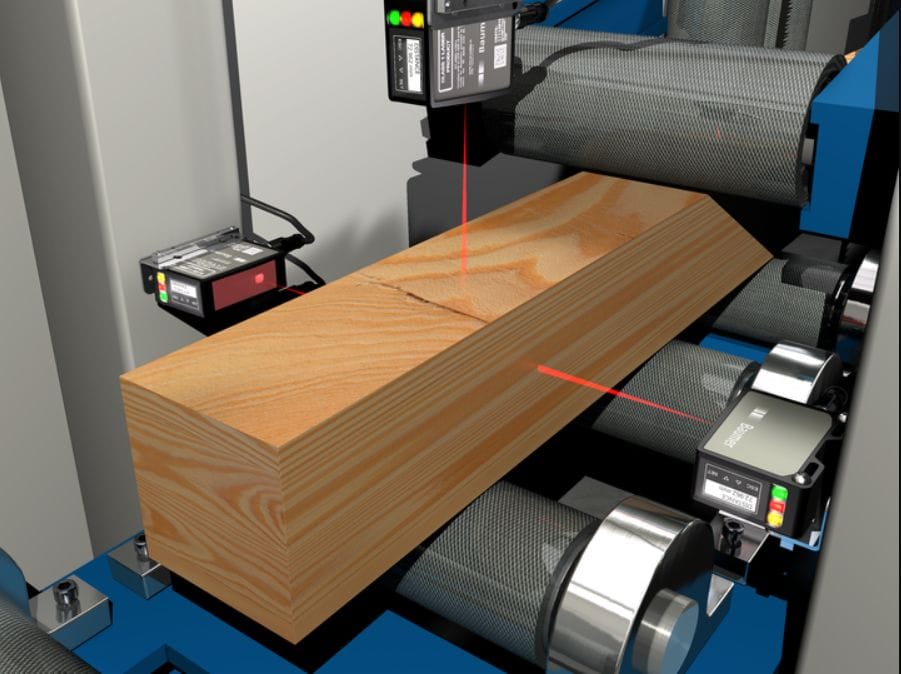

| Quality Control- Distance sensors are employed for quality control purposes in the inspection of manufactured goods.

- By measuring distances and dimensions, these sensors help identify any deviations from the specified standards, ensuring that only products meeting the required criteria move forward in the production process.

| Packaging Systems- In packaging applications, distance sensors help optimize the packaging process by precisely measuring the dimensions of products.

- This ensures that packaging materials are dispensed accurately and that the packaging process accommodates variations in product sizes.

|

Automated Guided Vehicles (AGVs)- AGVs use distance sensors to navigate through a facility, avoiding obstacles and maintaining safe distances from other objects in their path.

- These sensors contribute to the efficiency and safety of material handling in logistics and manufacturing environments.

| Assembly Line Processes- Distance sensors assist in the precise positioning of components during assembly line processes.

- They ensure that parts are correctly aligned, allowing for smooth and accurate assembly operations.

| Machine Safety- Distance sensors are integrated into safety systems to create safety zones around machinery.

- If a person or object enters these safety zones, the sensors can trigger an immediate stop or slowdown of the machinery, preventing accidents.

|